After brainstorming, the experts wanted to validate their ideas using MAGMASOFT ®.

#Doe magmasoft driver#

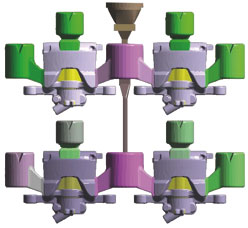

The last identified driver resulting in higher porosity was shrinkage due to an existing hotspot in the casting. A next possible root cause was hydrogen content in the melt. The second cause for the problems was related to oxides on the molten surface. Impurities and cold shut defects were assigned to a too slow melt velocity during filling. In the first brainstorming session, years of experience in foundry work allowed the employees at Akebono to directly narrow down all the possibilities to only the most likely root causes. The experts at Akebono had to find solutions for the defects to fight growing reject rates. Two of these three problems were even intensified, depending which gating system was used. In the production of one single part, three major casting defects showed up: Impurities on the surface, cold shuts and porosity (Fig. The company manufactures master cylinders in the gravity casting process using two different gating systems.

Akebono Brake Astra Indonesia is one of the foundries who implemented the methodology of MAGMASOFT ® autonomous engineering to support their experts and reduce uncertainty.

In this way, the realistic contact situation is modelled and the predicted distortion corresponds to reality at all times.įor further details contact Ametex on 0 or visit Ausleeren, Entkernen, Putzen, Rohgussnachbehandlung

All contact pairings are automatically detected and continuously updated based on the part and rack distortion. For example, distortion predictions can be evaluated and optimised with regard to their deviations from defined points, lines or angles.įor heat treatment simulations, significant improvements have been installed for automatic determination of contact between the component and the heat treatment rack. New optimisation objectives are available for users of stress simulations. The picking function can be used to display different results at defined locations. In the Result Perspective, numerous improvements have been implemented for fast display and evaluation of project results. For users of Magma C+M, it is possible now to interactively place nozzles from the parametric database onto the surface of the core geometry in a few simple steps. Together with Foseco, new datasets for SCK risers were added to the geometry database. In cooperation with Disa, the database for the Magmadisa module was updated for all current moulding lines. Typical application examples include assessing different flow velocities of gas and sand flow, or investigating the cooling behavior of air for drying inorganically bound cores. Users of Magma C+M can apply the new functions to evaluate flow with virtual particles for the design and optimisation of core production. For the design of the shot profile, various options are now available for evaluating curves for plunger speeds and the pressure curve reduced by the PQ² function. This simplifies the judgment of complex, flow-relevant questions.

#Doe magmasoft windows 7#

Magmainteract can be downloaded free of charge for use with Microsoft Windows 7 or higher.įor die-casting processes, temperature, velocity, and pressure results, as well as the gate from which the melt originated, can be displayed and animated directly on virtual particles (tracer particles). With the current release, MagmaSoft users can select results, export and make these results available to third parties in the compressed Magmainteract format. All results can be rotated, zoomed and panned by the user. Magmainteract offers interactive displays of all MagmaSoft 3D results, animations of mould filling (including with tracer particles) and the solidification process, visualisation of all results and criteria, including distortion for previously defined cross-sections and the interactive evaluation of virtual designs of experiments in a parallel coordinate diagram. This presentation promotes communication within the manufacturing organisation, as well as between suppliers and customers. The first development is Magmainteract, a visualisation function for MagmaSoft results, a free 3D viewer that allows intuitive visualisation of information exported from MagmaSoft 5.4.1.

#Doe magmasoft software#

Recently Magma introduced its new release, MagmaSoft 5.4.1, the MagmaSoft modular simulation software for casting design and optimisation, with numerous new capabilities and improvements for virtual prediction and optimisation for all casting processes, including continuous casting and core production.

#Doe magmasoft plus#

New release includes a free visualisation function, plus new capabilities and improvements for virtual prediction and optimisation for all casting processes, including continuous casting and core production.

0 kommentar(er)

0 kommentar(er)